Inspection Stamps: Types, Uses, and Benefits for Quality Assurance

Inspection stamps play a crucial role in maintaining quality and compliance across various industries. These small yet powerful tools help ensure that products meet specific standards and regulations. In this blog post, we will delve into the world of inspection stamps, exploring their uses, types, customization, and the information typically included on them.

What Are Inspection Stamps?

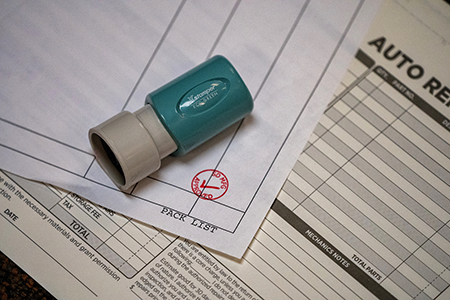

Inspection stamps are tools used to mark or stamp products, documents, or packaging to indicate that they have been inspected and meet certain quality standards. These stamps are commonly used in manufacturing, quality assurance, and regulatory compliance processes. The concept of inspection stamps dates back to when quality control became a significant aspect of industrial production, ensuring that only the best products reached the market.

How Are Inspection Stamps Used and What Are Their Benefits?

Inspection stamps are primarily used for quality assurance, ensuring that products meet the required standards before they are distributed or sold. They also help in compliance with various industry regulations, making it easier to track and trace inspected items. Additionally, inspection stamps provide a reliable method for recording the inspection process, facilitating accountability and transparency in production lines. Inspection stamps are a key factor to maintaining high standards of quality, which is essential for customer satisfaction and brand reputation.

Who Orders Inspection Stamps and How to Order

Inspection stamps are ordered by a wide range of industries and sectors, including manufacturing, automotive, aerospace, pharmaceuticals, and food processing. These stamps are essential in any industry where quality control and regulatory compliance are critical. Common use cases include marking approved or rejected items, indicating inspection dates, and providing traceability for various components and products.

Ordering inspection stamps involves selecting the right type, customization options, and ink type to meet specific needs. It's essential to choose a reputable supplier who can provide high-quality stamps that meet industry standards. The ordering process typically includes specifying the desired features, such as size, design, and information to be included on the stamp.

Types and Features of Inspection Stamps

There are several types of inspection stamps available, each suited for different applications and preferences. The main types include pre-inked stamps, self-inking stamps, and rubber stamps with ink pads. Pre-inked stamps offer clean and precise impressions, self-inking stamps are convenient and easy to use, and rubber stamps with ink pads are versatile and customizable.

Customizing Inspection Stamps and Information Typically Found

Inspection stamps typically contain essential information that facilitates the quality control process. Common elements include the company name or logo, the date and time of inspection, the inspector’s name or ID, and approval or rejection indicators. This information helps track the inspection process, ensuring accountability and providing a clear record of quality assurance activities.Inspection stamps must comply with various industry-specific standards and regulations. These standards ensure that the stamps provide accurate and reliable information, contributing to overall quality and safety. Regulatory compliance is particularly important in industries such as aerospace, pharmaceuticals, and food processing, where strict guidelines govern the inspection and approval processes.

Conclusion

Inspection stamps are invaluable tools for ensuring quality and compliance in various industries. By understanding their uses, types, and customization options, businesses can effectively implement inspection stamps to enhance their quality control processes. As technology advances, inspection stamps will continue to play a vital role in maintaining high standards of quality and safety.

FAQs

- What is the primary purpose of inspection stamps?

- Inspection stamps are used to mark items that have been inspected and approved, ensuring they meet quality and compliance standards.

- What industries commonly use inspection stamps?

- Industries such as manufacturing, automotive, aerospace, pharmaceuticals, and food processing commonly use inspection stamps for quality control.

- Can inspection stamps be customized?

- Yes, inspection stamps can be customized with company names, logos, dates, inspector names, and approval indicators.

Happy stamping,

The crew at stampersDIRECT!

Leave your comment